MX 1020 automatic screen printer.

it is suitable for 105-350g/m ² materials,especially for paper productions(such as cigarette or wine case,toiletry case,present case ,brand,poster,other paper packing production and special fake against material etc)flower paper ,soft plastic

- Product Introduction

AUTOMATIC CYLINDER SCREEN PRINTER

| PRICE | 1020type size fob 49000usd (4UV lamps+1 IR lamp +guards+ stacker ) |

| DELIVERY TIME | 30 workdays |

| PAYMENT ITEMS | 30% by T/T for deposit. The balance of 70% should be paid by T/T before shipment. |

| optional | Machine full line elevation ( stacker height 1150mm )price 71500usd ,pre-stacker (2m length)price 2400usd ,transfomer :1000$ ,

UV lamp :80 $/pcs , IR lamp :20$/pcs |

USE & FEATURES:

- MX series full automatic cylinder screen press is kind of automatic flat screen press with high efficiency (more than diploid printing speed over the flat one),high quality and high

- it is suitable for printing of high precision screen

- it is suitable for 105-350g/m ² materials,especially for paper productions(such as cigarette or wine case,toiletry case,present case ,brand,poster,other paper packing production and special fake against material etc)flower paper ,soft plastic

- Automatic computing printing, and calculate the qty, and printing can be set automaticallystop

PARAMETERS:

| 型号 Model | MX-1020 |

| 最大印刷尺寸/Max.printing size | 1020x720mm |

| 最小纸张尺寸/Min.paper size | 350x560mm |

| 最大纸张尺寸/Max.paper size | 1050x780mm |

| 咬口/Border | ≤15mm |

| 纸张厚度/Paper thickness | 90-400gsm |

| 网框尺寸/Screen frame size | 1280x1140mm |

| 最高印刷速度/Max.printing speed | 1000-3000pcs/h |

| 堆垛高度 Stacker height | 700mm |

| 重量/Weight | 5000kg |

| 电压功率/Power(kg) | 3P4N 50/60HZ 380V 15KW |

| 尺寸/Dimension(LxWxH) | 4570x2700x1430 |

M a i n F e a t u r es :

1.The feeder:

|

Cylinder stops step automatically to ensure the forehead of the printing stock can be sent accurately to the gripper of cylinder,which is up to extreme high precision.A large cylinder shaft and specially made high precision bearings ensure the highest quality printing at higher speed.

2.Feed board

|

The vacuum absorb is assembled in the bottom of the feed board,matching with the push and press paper construction,in sure various materials all can be delivered smoothly.

3.Cylinder system

|

Cylinder stop step automatically to ensure the forehead of the printing stock can be sent the accurately to the gripper of cylinder,which is up to extreme high precision.A large cylinder shaft and specially made high precision on bearings ensure the highest quality printing at higher speed.

4.Squeegee and screen system:

|

Squeegee and ink return blade are driven by individual cams and a two-step action cam helps reduce the squeegee shock onto the screen mesh;Due to the positive down cam action,the printing pressure is evenly applied to the cylinder continuously,squeegee with the pneumatically pressure kept device,resulting in sharp dot reproduction,the printing graphics is more clearly and the ink layer is more well-proportioned.

5.Register system:

|

The machine adopts the pull/push side lay design by non-stop regulation device.pull/push side-lay both have sensors for supervising if the printing stock is in correct place.

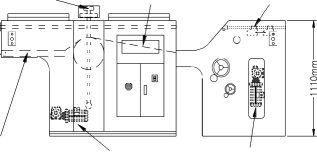

MACHINE INTRODUCE:

(Paper rack motor) (Scraper, reink knife holder) (Paper feed table) (Paper feed)

(Out of the paper board) (Ink knife lifting motor) (Paper feed table lifting motor)

Acting stand Printing machine Feida

Structure diagram

Feeder part is mainly composed of Feeder, feeding table, feeding board, lifting motor of feeding table and control panel. Its purpose is to send paper or other prints automatically, continuously and accurately to the printing department of the main engine, whose power is provided by the main motor.

The main part, also known as the printing department, consists of cardboard feeding, printing drum, scraper and ink return knife, screen frame, paper outlet and corresponding control parts. The ma in function of the main part is printing, and other functional components are used to ensure the printing accuracy, as well as receiving and delivering the prints to the printing cylinder from the paper part, and delivering the f inished prints to realize t he full automatic printing process.

CONFIGURATION:

| NO. | Name | Model | Qty | Trademark | Place |

| 1 | Main motor | 3-PHASE INDUCTION

MOTOR 2.2KW,0.37KW |

2 | STS | Taiwan |

| 2 | Printing motor | 2 | LIANCHENG | Taiwan | |

| 3 | AC Contractor | LC1D2501M5N 220V | 1 | SCHNEIDER | Germany |

| 4 | AC Contractor | LC1D1201M5N220V | 9 | SCHNEIDER | Germany |

| 5 | Time Relay | H3BA-N8H AC220V | 1 | OMRON | Japan |

| 6 | Inverter | 2.2kw,0.75kw | 2 | TOSHIBA | Japan |

| 7 | Photo electricity sensor | E32-ZD200 DC10~30V | 3 | OMRON | Japan |

| 8 | PC Control Module | 1 | SIMENS | Germany | |

| 9 | Approach Switch(Quadrate) | TL-Q5MC1 | 3 | OMRON | Japan |

| 10 | Approach Switch(Circular) | E2A-M12KN08-WP-C1 | 2 | OMRON | Japan |

| 11 | Control Button | ZB2-BA5C | 9 | SCHNEIDER | Germany |

| 12 | Power Switch | ZB2-BC4C | 3 | SCHNEIDER | Germany |

| 13 | Breaker | OSMC32N Series | 6 | SCHNEIDER | Germany |

| 14 | Printing Guide Block | OSMC32N Series | 4 | SBS | South Korea |

| 15 | Printing Guide | SBS25SL-K1-N | 2 | SBS | South Korea |

| 16 | Selective Switch | 4 | SCHNEIDER | Germany |

S E L E T I O N :

SLECT 一:suitable for the UV screen printing.

1.Including MX1020 Automatic Cylinder Screen Printing Machine

a. printing size:1020x720mm(normal 1020*700mm)

b. paper size:560x350mm

c. paper size:1020x720mm

d. Paper thickness:120-400gsm

e. Screen frame size:1140x1280mm

f. printing speed:1000-3000sheets/h

g. Total power:10.25kw

h. Weight:5000kg

i. Overall dimension:4570x2700x1420mm

2.Including UV Dryerand IR heating

a. Lamp power:8.0kw*4pcs(UV)+IR with Wrinkle Lamp

b. Belt width:1050mm

c. Weight:600kg

e. Overall dimension:6000x1450x1650mm

3.Including Automatic Stacker Machine

a. paper size:1020x720mm

b. paper size:350x270mm

c. Paper stacking height:700mm

d. Weight:650kg

e. Overall dimension:2000x2050x1350mm

Accessories of machine ( need extra purchase )

| Product | Price |

| 1280×1140 mm aluminum frame | 73$/pcs |

| UV lamp 8.0kw 1180mm | 80$/pcs |

| IR lamp | 20$/pcs |

| 5040mm*1100mm Belt

|

160$/pcs |

| 7040*1100mm Conveyor Belt | 210$/pcs |

| Scraper rubber strip 3.5m | 105$/box |

Machine picture :

Feature:

Use on the UV series screen printing,include UV spot varnish、UV full varnish、UV polish、UV refraction、UV

foaming、colorful crystal,etc.printing of special effect and anti-counterfeiting effect.

Remark:UV&IR The number of infrared, ultraviolet and cooling sections of the combined infrared and ultraviolet dryer can be reconfigured and matched according to the different needs of users. The above data are the standard configuration at the time of leaving the factory.

A.Other Mentions:

1、To buyer plant installation.

2、Parts other than consumables shall be guaranteed for one year under normal maintenance and service conditions.

3、The machine has the right to improve.

B.Buyer-Owened Project:

- The main power supply wiring outside the electric control box of this machine is buried with works and gas

- On-site mechanical lifting and unloading operation. RUNNING:

One dryer :

Optional :

Screen printing plate making machine

| No. | Name | Specification | Price usd |

| 1 | Baking Machine | 2000$ | |

|

|

Model: MX-H-1500

Total power:4.1kw Input voltage:380V 50/60HZ Max.frame size:1280x1140mm Total weight:200mm Overall Dimension:1650x1450x1700mm |

||

| 2 | Stretching Machine | 3000$ | |

|

|

Specification:

Model: ST1412 Air aply:0.8mpa Frame Max.size:1200x1400mm Weight:200kg Place size:1500x1800x750mm |

||

| 3 | Exposure machine | 2400$ | |

|

|

Model:MX-S1518

Frame size:1200x1500mm Lamp power:2.5kw Input voltage:220v/50~60hz Weight:230kg Overall dimension:1900x1600x1200mm |

||

| 4 | Scraping Machine 磨刮机 | 1500$ | |

|

|

1200mm length Weight:50kg Overall Dimension:1350x450x400mm |

||

|

Totoal amount |

Screen printing plate making machine including Baking Machine,Stretching Machine,Exposure machine,Scraping Machine 4 sets

|

8900$ |

|